Insight

5 organisational benefits of supply-chain mapping

Insight

5 organisational benefits of supply-chain mapping

To limit global heating below the ‘magic’ number of 1.5C, or even the way less magic number of 2C, businesses need to decarbonise, and decarbonise fast. One of the greatest challenges that businesses face in achieving this goal is reducing the emissions that they’re not directly responsible for, known as Scope 3 emissions.

An increasing number of businesses are starting to get a handle on, or at least plan to get a handle on, their Scope 1 and 2 emissions. But those pesky Scope 3 emissions are proving slippery.

While many organisations need to track how their energy-hungry products are being distributed and used after sale, others need to track their resource-hungry production processes to better understand the scale of their Scope 3 problems.

Supply-chain mapping won’t solve all of your Scope 3 problems, but it will at the very least take a big bite out of them.

What is supply-chain mapping?

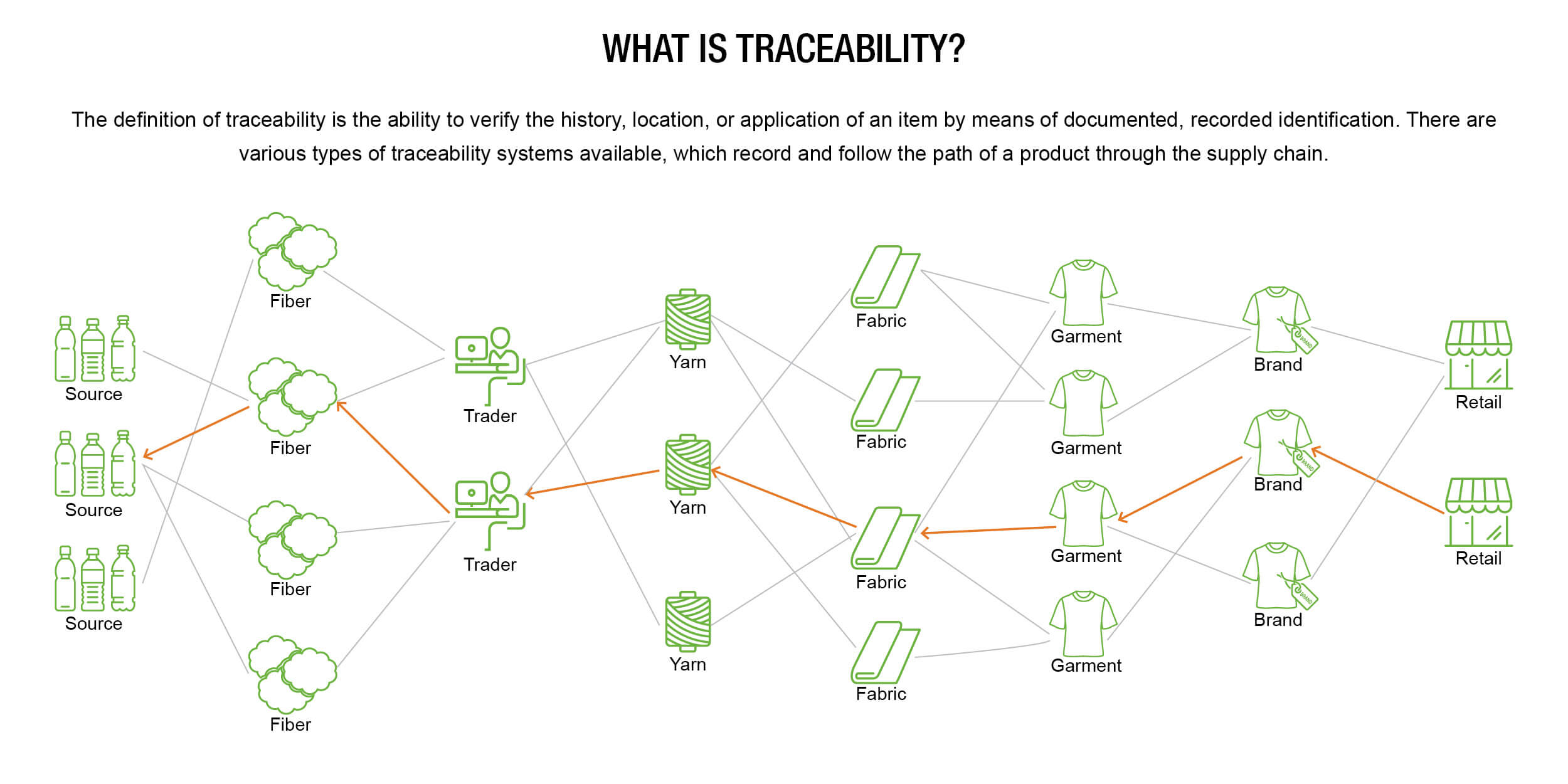

Supply-chain mapping is the process of identifying and documenting all of the steps involved in the production and delivery of a product or service. This includes everything from sourcing raw materials to delivering the final product to the customer. By mapping out the supply chain, companies can gain a better understanding of where their products come from, how they are made, and who is involved in the process. This is where the essential aspect of traceability comes into play.

In the example above from Textile Exchange, you can begin to understand what it takes to produce your t-shirts, sweaters or jeans. Each of these steps are different, requiring different inputs and generating different outputs. And, in many cases, they need transportation and distribution channels to keep everything moving.

If we can map out the supply chain, we can begin to understand where our sustainability hotspots might be, unearth best practices within the chain, and target areas that are negatively impacting the world around them.

So what are some of the key benefits of honing in on the various stages of the supply chain from a sustainability perspective?

Benefit 1: Supply-chain mapping flags environmental risks (and opportunities)

One of the key benefits of supply-chain mapping is that it can help companies identify potential environmental impacts or risks, as well as areas for improvement. For example, by mapping out their supply chains, companies can identify where they are using large amounts of energy, water or other resources, and where they are generating the most waste. This information can then be used to develop strategies to reduce environmental impacts and improve sustainability.

As an example, Abel & Cole have developed a unique labelling system across their fruit and vegetable range, assessing each individual line and giving their customers a view on how sustainable their shopping baskets really are. Abel & Cole achieved this through mapping their supply chain, gathering the data and using it to calculate the impact of each fruit and vegetable they sell.

Benefit 2: Supply-chain mapping highlights new ways to reduce emissions

Another benefit of supply-chain mapping is that it can help companies identify opportunities to reduce their carbon footprint. In pursuit of net zero, many organisations are now looking for ways to reduce their carbon emissions in order to meet their climate change commitments and to improve their environmental performance. By mapping out their supply chains, businesses can identify where they are generating the most emissions and where they can make the most impact by reducing them.

Mapping out their supply chain saw Unilever hit the realisation that raw materials and packaging account for around 60% of their emissions, meaning they had to focus their efforts on suppliers. One way they’re reducing emissions is by replacing fossil-fuel-derived carbon in their home care products with renewable or recycled carbon, thereby cutting emissions by 20%.

More generally, Unilever are also asking their key suppliers to lower their emissions in line with current climate science. That’s around 54,000 suppliers in total, so identifying those with the biggest impact enables Unilever to work closer together with them, and to provide advice and solutions where it makes the most difference.

Benefit 3: Supply-chain mapping can champion more sustainable materials

Supply chain-mapping can also help companies identify opportunities to use more sustainable materials and products. High-street retail is already awash with brands launching eco-friendly product lines in an effort to attract more conscious consumers. You can even buy a wedding dress made from ocean plastic these days, and the list of everyday products made from recycled materials keeps on growing.

Companies can use the information gathered through supply-chain mapping to identify where they are using products or materials that are not environmentally friendly and where they can switch to more sustainable options. For instance, companies may choose to switch to renewable energy sources or to use more eco-friendly packaging materials. Ultimately, this can help to reduce environmental impacts and enhance the push towards sustainability.

Benefit 4: Supply-chain mapping boosts traceability and transparency

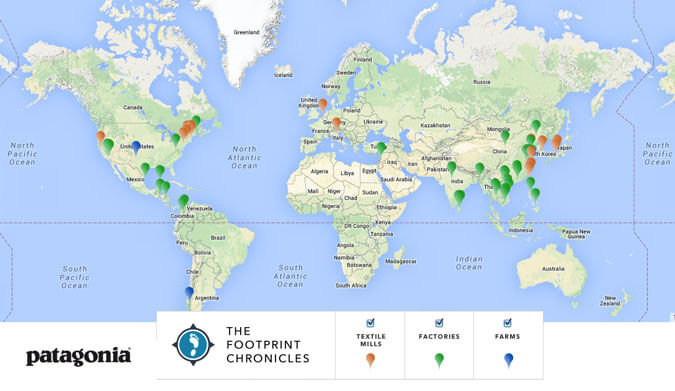

Mapping out complex supply chains is an effective way for companies to improve transparency and traceability, which are again high on the consumer agenda. In doing so, companies can identify where they are sourcing their materials and products and who is involved in the production process. This can help ensure that the products they are sourcing are ethically and sustainably produced, and that they are not contributing to human rights abuses or environmental degradation.

Patagonia are a great example of an organisation who have worked hard to map out their supply chains to better understand where their products come from and ensure that they’re sourced ethically.

On the flipside, a recent episode of BBC’s Panorama unveiled ‘The True Cost of Our Tea’, with reports of sexual exploitation of women at Kenyan tea plantations that ultimately supply the likes of UK household name brands like PG Tips and Lipton.

Benefit 5: Supply-chain mapping forges stronger relationships

Lastly, supply-chain mapping can help companies to build stronger relationships with their suppliers, customers and other partners. By understanding the supply chain and the role that different actors play in it, companies can identify areas where they can collaborate and share best practices to improve their environmental performance and sustainability. This can serve to create a more sustainable supply chain overall.

Tony’s Chocolonely is a fantastic example of this, taking on the traditional cocoa supply chain with a view to eradicating slavery within the industry as a whole, not just their own products. While they haven’t escaped controversy completely, they have shown that working with suppliers and forging long-term relationships with them has significantly reduced instances of child labour.

Critically, the Tony’s approach is not simply to stop working with suppliers that are engaged in child labour. The cocoa supply chain is massively complex and institutionally unfair to suppliers, meaning these are often family units, often forced to draw in their own children to work the farms. Instead, Tony’s have worked with farmers to come up with longer-term solutions that benefit the farmers while improving the quality of their product. As a result, this kind of initiative sits right at the intersection of sustainability and social justice.

We can help you join the dots in your supply-chain data

As companies are becoming more conscious about their environmental impacts, supply-chain mapping offers a powerful tool for improving sustainability and reducing the negative impacts of their operations on the environment.

Supply-chain mapping offers a variety of organisational benefits, especially when it comes to ESG initiatives (and CSR more generally). Mapping out your data in this way can help you identify and mitigate any red-flags quickly, as well as longer-term areas for improvement as part of your organisation-wide strategy on sustainability.

By combining subject matter expertise in sustainability with our data design credentials, we can help you visualise your organisation’s supply chain, however complex it may be.

Do you want to gain greater clarity on your supply chain’s sustainability performance? Talk to Stewart about running one of our Lunch & Learn sessions for you and your team.